Home / services

· One-Stop Service Provider For Can Production Line

The customization scope includes equipment selection and configuration, efficiency upgrades, and container design services. Our goal is to ensure that the can production line is efficient and precise in producing cans that meet the quality requirements and product requirements.

- Device selection and configuration: According to your needs and requirements, we can choose the appropriate equipment, such as a slitting machine, automatic welding machine, internal spray machine, neck machine, flanging machine, plate rolling machine, and can sealing machine. We consider the speed, specifications, and functions of different equipment to meet your production needs.

- Efficiency upgrade: If your existing three-piece tank production line has problems with efficiency or quality, we can make improvements in the upgrade. For example, replace old welders to improve welding quality and production efficiency.

- Container design services: If you have specific container needs, such as milk powder cans, chemical cans, or high-pressure cans, we can provide corresponding design services. Depending on your needs, we can adjust or customize the equipment to ensure that the equipment can meet the special requirements of the container.

- We will work closely with you to ensure that the overall requirements of the can production line or the corresponding parameter requirements are fully understood. For example, you may need to provide requirements for canning speed, i.e. the number of cans produced per minute; Range of tank diameters to determine applicable equipment specifications; And whether you need to produce a traditional standard tank shape, or you need to make an irregular shape tank.

- If you have to provide drawings or design requirements, we will design and choose the right can-making equipment according to your requirements. If we do not yet have the right specifications for your needs, our technical team will work with you to create a custom design. Once the design is confirmed, we will begin to arrange production and go through rigorous testing to ensure that the quality and performance of the product meet your requirements.

- After the canning equipment arrives at your plant, we offer online training or on-site installation training to ensure that you can use our equipment smoothly. In addition, we also provide after-sales service and maintenance support to ensure the normal operation and use of the equipment.

More Benefits Of Choosing Us

Our ability and professionalism are reflected in our products and services. You can trust everything we do and any advice we provide for you.

-

Adjustable production line speed: Our equipment can adjust the running speed of the production line according to your needs to adapt to different production requirements. For high volume requirements, we can provide high line speeds and improve production efficiency.

-

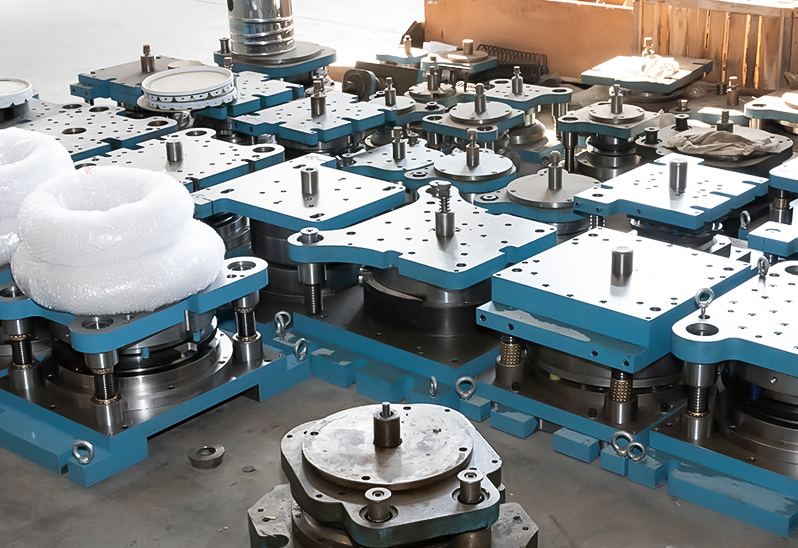

Mold-replaceable: Our can-making equipment is equipped with a replaceable mold system, which can flexibly adapt to the production of metal cans of different specifications and shapes. By changing the mold, metal cans of different sizes and shapes can be produced.

-

Automatic control system: Our canning equipment adopts an advanced automatic control system, which can be adjusted flexibly according to needs to meet the production requirements of different products. By adjusting the parameters, the size, shape, and production speed of the tank can be controlled.

-

Customized process flow: We can customize the process flow of canning equipment according to your specific needs. According to the production requirements and process standards of different metal cans, we can carry out personalized designs and adjustments to ensure your product quality and production efficiency.

-

Based on our experienced team and technical support, we ensure that you can provide cost-effective canning equipment. We will use high-quality materials and components, combined with advanced technology, to ensure the high quality and reliability of the equipment.

-

We attach importance to after-sales service and provide after-sales support and spare parts supply to ensure the normal operation of equipment during use. Whether it is maintenance or replacement of spare parts, we will provide timely response and support to ensure continuous production of the equipment.

English

English русский

русский عربى

عربى