The correct use method of the automatic sealing machine:

1. There is always a certain amount of butter (molybdenum disulfide smooth grease) in the gear box of the automatic can sealing machine.

2. The automatic sealing machine needs to refuel once in the American class of butter nozzle.

3. Before the needle roller bearing and cylindrical roller bearing device, each ring should be coated with smooth oil.

4. Each radial bearing (headed by 6) should have an oil seal on both sides.

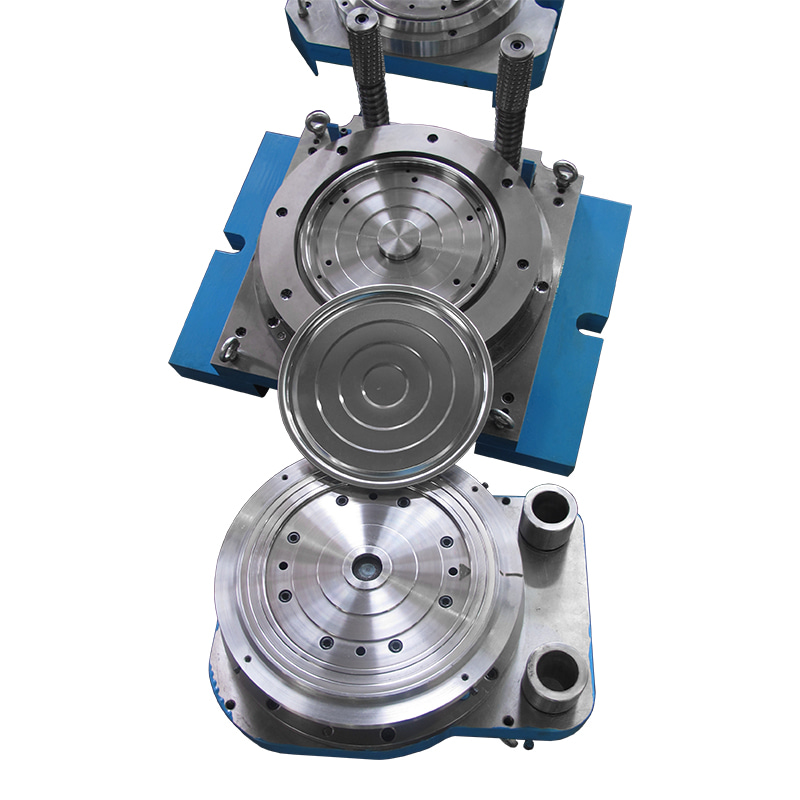

5. For tanks with different diameters, use a turntable and indenter with different positioning arcs.

6. The round pin φ8 of the part number 24# should be pressed in, and then a thin spring steel sheet z (thickness d = 0.5 ± 0.02 after being ground by a surface grinder) is used to adjust the gap between d = 0.03-0.05, and Always refuel and smooth.

7. Part No. 41# flat bearing should also be greased during use.

8. The shape and layout of the sealing roller and roller shaft are for reference only.

9. Turntable materials South Korea uses hard plastic, the world uses bakelite or aluminum alloy plates. The is not to attract magnetism, the second is to be easy to process and the accuracy is maintained, and the third is not to deform. Please choose reasonably.

11. The automation of electrical appliances, cutting, indexing, and cylinder hexie produces motion effect plc control, which is planned by electrical engineers.

12. It is necessary to add a motor-less conveyor belt for the automatic can sealing machine, which is used for emptying the can at the inlet side, and the length is about 2mm.

English

English русский

русский عربى

عربى

Contact Us