Provide you with the latest enterprise and incustry news

Web Menu

Product Search

Exit Menu

What is the principle of the automatic sealing machine

Fully automatic can sealing machines are generally used in automated production lines and mass production lines. Since the model is converted from a drilling machine, the current domestic can seamers are large and heavy Can sealing machine . Because of the high cost, high output, and high technology, it is deeply favored by large enterprises.

Related Products

-

1-5L Round Can Production Line Picture Sample_b Configuration

Cat:1-5L Round Can Production Line

The 1-5L round can production line configuration diagram shows an automated production line that can efficiently produce round metal cans with a capac...

See Details -

18L Pail Production Line

Cat:18L Pail Production Line

18L Pail Production Line is a production line specially used for manufacturing large barrels with a capacity of 18 liters. It usually includes raw mat...

See Details -

55 CPM 18-20L Pail Body Automatic Production Line

Cat:18L Pail Production Line

18-20L Pail Body Automatic Production Line is a highly efficient and automated production line specially designed for producing plastic pails with a c...

See Details -

Lk/Qdy400 Pneumatic Pre-Bending Machine

Cat:Vacuum Cleaner Pail Production Line

This machine is suitable for the front process of hollow crimping. After pre-bending, the yield of the back winding is increased, and the winding do...

See Details -

200L Round Expanding Machine

Cat:200L Drum Production Line

200L Round Expanding Machine is a highly efficient and automated blow molding equipment specially designed for producing 200L round plastic barrels. I...

See Details -

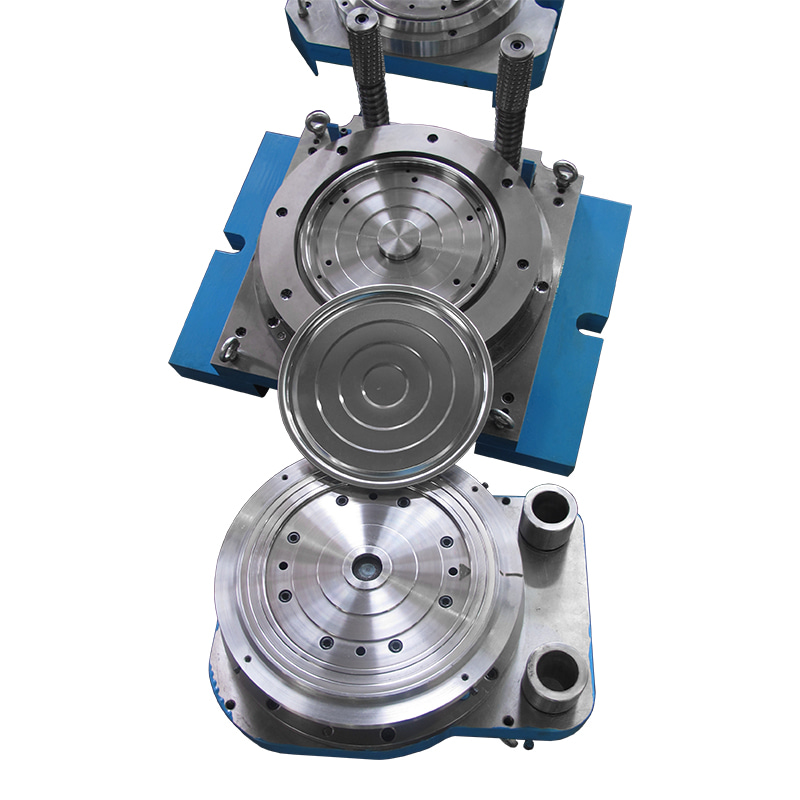

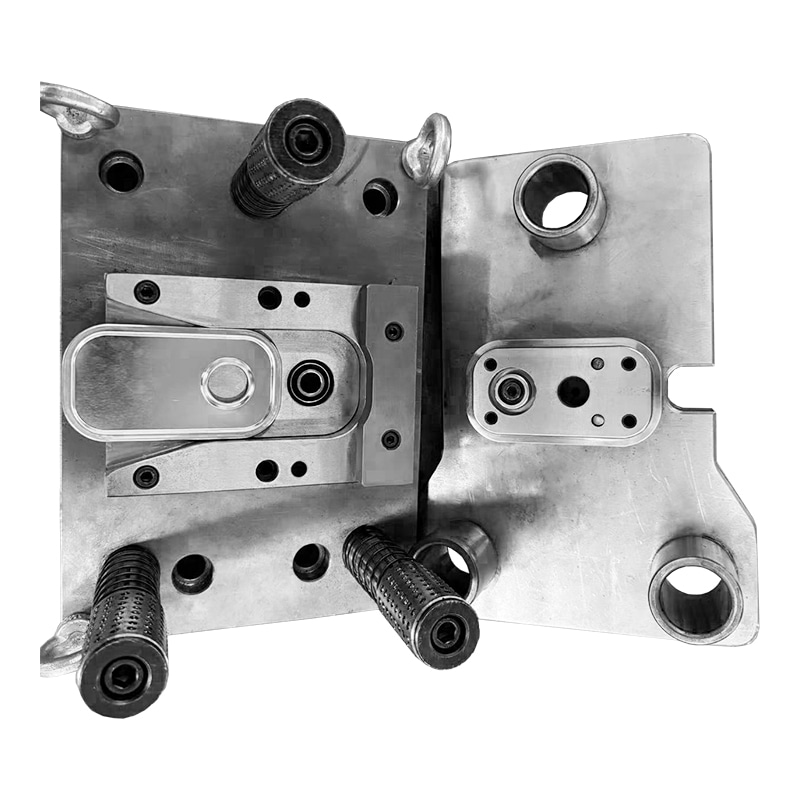

Three-Roller Automatic Can Sealing Machine

Cat:Automatic Can Seaming Machine

The three-roller automatic can sealing machine is a highly efficient automated packaging equipment, widely used in food, beverage, chemical and other ...

See Details -

1-5L Round Can Production Line Picture Sample_b Configuration

Cat:1-5L Round Can Production Line

The 1-5L round can production line configuration diagram shows an automated production line that can efficiently produce round metal cans with a capac...

See Details -

18L Pail Production Line

Cat:18L Pail Production Line

18L Pail Production Line is a production line specially used for manufacturing large barrels with a capacity of 18 liters. It usually includes raw mat...

See Details -

55 CPM 18-20L Pail Body Automatic Production Line

Cat:18L Pail Production Line

18-20L Pail Body Automatic Production Line is a highly efficient and automated production line specially designed for producing plastic pails with a c...

See Details -

Lk/Qdy400 Pneumatic Pre-Bending Machine

Cat:Vacuum Cleaner Pail Production Line

This machine is suitable for the front process of hollow crimping. After pre-bending, the yield of the back winding is increased, and the winding do...

See Details -

200L Round Expanding Machine

Cat:200L Drum Production Line

200L Round Expanding Machine is a highly efficient and automated blow molding equipment specially designed for producing 200L round plastic barrels. I...

See Details -

Three-Roller Automatic Can Sealing Machine

Cat:Automatic Can Seaming Machine

The three-roller automatic can sealing machine is a highly efficient automated packaging equipment, widely used in food, beverage, chemical and other ...

See Details

-

gt4a28-zd automatic sealing and sealing machine factory custom direct sale (graphic)

Reference Price: RMB 39000.00 (Please consult for the latest quotation) Starting batch: ≥1 set...

-

[Low noise] gt4a28f pneumatic sealing machine [wholesale price]

price: 32000.00 yuan (Reference price, please consult for the latest quotation) Starting batch...

-

Add a new chapter to the product---Fully-automatic lid-dropping can-sealing machine (picture and text)

After repeated demonstrations, tests and modifications, Lucky once again launched new products, whi...

-

The website of Zhoushan Dinghai Lekai Can Machinery Factory is online!

Dinghai Lekai Can Making Machinery Factory is located on the coast of the East China Sea, the beaut...

-

[Semi-automatic round tin can sealing machine] price

Reference price: 18000.00 yuan (for the latest quotation, please consult) The main technical...

-

gt4a28-zd automatic sealing and sealing machine factory custom direct sale (graphic)

Reference Price: RMB 39000.00 (Please consult for the latest quotation) Starting batch: ≥1 set...

-

[Low noise] gt4a28f pneumatic sealing machine [wholesale price]

price: 32000.00 yuan (Reference price, please consult for the latest quotation) Starting batch...

-

Add a new chapter to the product---Fully-automatic lid-dropping can-sealing machine (picture and text)

After repeated demonstrations, tests and modifications, Lucky once again launched new products, whi...

-

The website of Zhoushan Dinghai Lekai Can Machinery Factory is online!

Dinghai Lekai Can Making Machinery Factory is located on the coast of the East China Sea, the beaut...

-

[Semi-automatic round tin can sealing machine] price

Reference price: 18000.00 yuan (for the latest quotation, please consult) The main technical...

-

gt4a28-zd automatic sealing and sealing machine factory custom direct sale (graphic)

Reference Price: RMB 39000.00 (Please consult for the latest quotation) Starting batch: ≥1 set...

-

[Low noise] gt4a28f pneumatic sealing machine [wholesale price]

price: 32000.00 yuan (Reference price, please consult for the latest quotation) Starting batch...

Copyright LK MACHINERY CO., LTD. All Rights Reserved Easy Open Tin Can Machine Factory Custom Can Making Machine Manufacturer

English

English русский

русский عربى

عربى

Contact Us