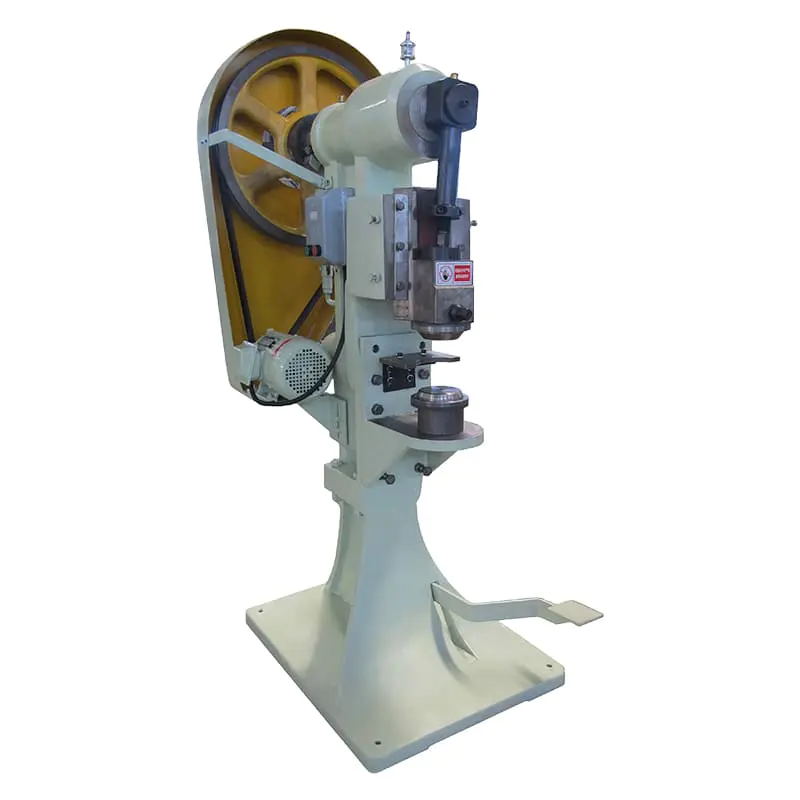

Explanation of the operation steps of can making machinery:

step:

1. Boot

2. Press the start button or turn on the reverse switch.

3. Observe whether the direction of the turntable of the sealing machine is consistent with the direction of the arrow marked on the outer cover of the sealing machine.

4. Now loosen the top rod screw of the lower body, put the cuffed can body on the bottom cover or the face cover, put it in the pressure head, and then put the foot pedal, and then turn the screw rod upward or Move down until the clutch pin closes the clutch and then closes the driving gear and the driven gear to generate a differential. The sealing wheel rotates around the pressure head to make a feed movement. After a week, the clutch disengages the carrier plate and the tank. The body is dropped to complete the sealing process. The above adjustments are suitable for the model that the can body does not move and the sealing turntable rotates. As for the other type of adjustment method for the can sealing model when the can body rotates when the can body rotates: turn the flanged can Put your hand on the supporting plate, step on the foot pedal, watch whether the height of the can body exceeds the upper edge position of the indenter by 5-8mm, and then tighten the ejector screw.

5. First try to seal 1~5 cans to observe the effect of sealing the cans, to see if there are any phenomena such as pulling edges, peeling paint, edge teeth, false sealing, leakage, etc., if the condition is good, it can be produced.

2. Shut down

1. Press the stop button or close the reverse switch.

2. Pull down the power air switch of the machine.

Precautions:

1. Pay attention to whether the sound is abnormal during the rotation of the machine.

2. Pay attention that the bottom cover is thrown out and scratched during operation.

Machine maintenance:

1. Lubricate the lubrication point of the machine regularly after get off work every day.

2. Regularly clean up oil and debris in the machine range after get off work every day.

3. Check whether the connecting screws around the machine are loose.

English

English русский

русский عربى

عربى

Contact Us